Copyright © 2019 Jiefusen(Shanghai) Environmental Protection Technology Co., Ltd. All right reserved.

DesignBy:ShuangXi

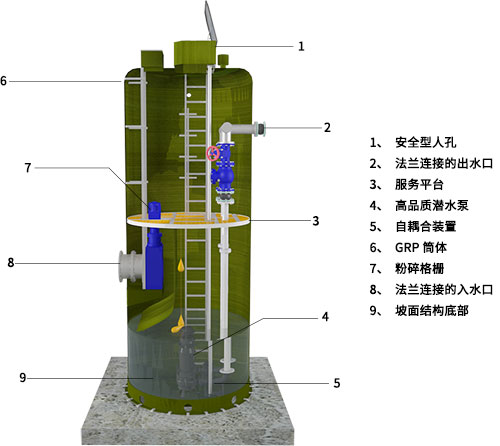

The integrated pumping station adopts the on-demand prefabrication method, which is prefabricated according to the requirements of the customer and the on-site inspection and measurement results of the engineer, and customizes the overall pumping station that meets the customer's needs. The internal equipment such as water pump, valve pipeline, sensor device and intelligent control system are installed and debugged, transported to the project site, and directly hoisted at the site, effectively solving various problems in the construction and operation of the pump station.

Order Hotline:

+86-4007800879Epsilon can tailor the product type according to your industry, site to be used and other special needs.

Offer consultingFeatures:The main body of the integrated prefabricated pumping station is made of glass fiber-reinforced composite material (glass fiber reinforced plastic/GRP), which has high strength, no deformation, long-lasting durability and long service life of more than 50 years. Technical advantages:The overall quality of the integrated prefabricated pumping station has passed CE safety certification and obtained relevant certification. Personalized customization:The integrated prefabricated pumping station is designed to meet a wide range of sizes, parameters and meson specificities. Maintenance free design:The CFD fluid dynamics simulation design is used to design the bottom of the self-cleaning to minimize the sedimentation at the bottom to avoid clogging. At the same time, it can effectively suppress the generation of toxic and malodorous gases and protect the environment. Intelligent remote control system:The pumping station is equipped with a centrally managed database and web server. Users only need to use the smartphone and computer with Internet access to understand the operation status of the pumping station, such as running time, load point, set point and sensing value. , alarms, etc. |  |

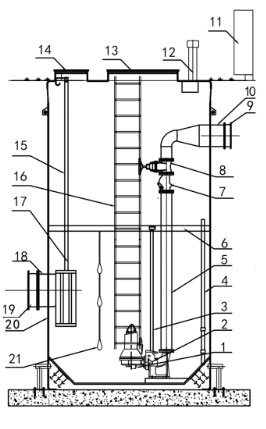

| Num | Name |

1 | Sewage pump | |

2 | Self-coupled base | |

3 | Water pump guide | |

4 | Liquid level sensor protection tube | |

5 | Pressure pipe | |

6 | Service platform | |

7 | Check valve | |

8 | Gate | |

9 | Outlet pipe flexible joint | |

10 | Outlet pipe | |

11 | Electrical control cabinet | |

12 | Ventilation duct | |

13 | Safety grille | |

14 | Manhole cover | |

15 | Grille guide | |

16 | Ladder | |

17 | Basket grille | |

18 | Inlet pipe | |

19 | Inlet pipe flexible joint | |

20 | Pump station cylinder | |

21 | Redundant float |

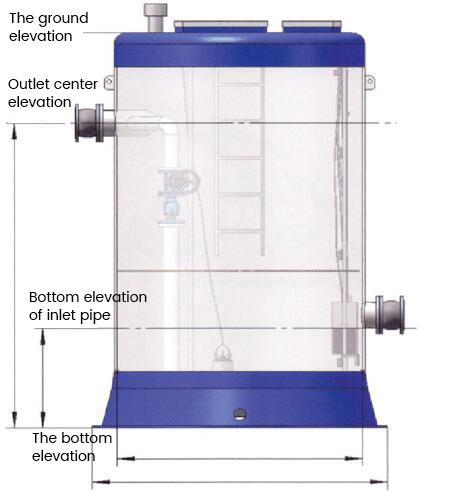

Pump station parameters:Design flow, lift The number of pumps required, including the working pump and the backup pump Ground elevation, inlet/outlet elevation Inlet/outlet pipe diameter Application and installation:Application areas: municipal engineering, industry, construction or other Installation requirements: indoor / outdoor, ground / underground structure type:External valve well wet pump station Built-in integrated wet well pumping station Joint pumping station Horizontal pumping station Control System:On-site automatic liquid level control, remote control |  |

Num | Product name | Standard material | Optional material and configuration |

1 | Prefabricated barrel and base | FRP GRP | |

2 | Top of the well | FRP GRP | |

3 | Self-cleaning disk | FRP GRP | |

4 | Manhole cover (manhole) | Aluminum alloy | Stainless steel AISI304 |

5 | Secondary operating platform | FRP GRP | |

6 | Ventilation duct | Stainless steel AISI304 | |

7 | Handrail ladder | Stainless steel AISI304 | |

8 | Water pump | Grey cast iron GG25 | |

9 | Basket type grille | Grey cast iron AISI304 | Crushing grid |

10 | Autotransformer and base | Grey cast iron GG25 | |

11 | Rails and chains | Stainless steel AISI304 | |

12 | Anchor platen | Steel plate | Stainless steel AISI304 |

13 | Bottom anti-corrosion anchor | SSP-MJ Hot galvanized steel | |

14 | Tightening | Stainless steel AISI316 | |

15 | Check valve | Cast iron | Stainless steel AISI304 |

16 | Gate valve | Cast iron | Stainless steel AISI304 |

17 | PN10 pressure pipe | Stainless steel AISI304 | PE、GRP、AISI316 |

18 | Inlet and outlet manifold and flange | GRP | PE、AISI304 |

19 | Pump station control cabinet | Stainless steel AISI304 Outdoor type | Pump station unmanned monitoring platform |

20 | Fully sealed sneak | ||

21 | Lifting device | ||

22 | Inlet pipe set | ||

23 | Mixer and mounting accessories | ||

24 | Deodorizing device |

Num | Fault content | Failure analysis | Solution |

1 | Trip, jump open | Large motor load, severe overcurrent | Close the water valve and increase the resistance |

Broken line, causing a short circuit | Check line | ||

Motor short circuit | Replace the motor | ||

2 | Motor noise | Bearing lack of oil | Add butter |

Overload operation | Close the small outlet valve to increase resistance | ||

Motor reversal | Adjusting the motor line | ||

3 | The motor is running, no water | Motor reversal | Adjusting the motor line |

Pump blockage | Cleaning pump | ||

Check valve can not be opened | Inspection check valve | ||

4 | The motor runs, the water tank turns over, but there is no water. | Check valve is not tightly closed | Replace check valve |

Water pump and separator are connected to leak | Fastening connection | ||

Separator seal is not strict | Check the separator and replace the gasket | ||

5 | Manual and automatic can not be started | Control cabinet short circuit | Check and fix |

Neutral disconnection | Check the zero line | ||

Fuse protection | Check if the output line is shorted | ||

Fault protection | Pump overload, shut off water valve | ||

Incoming line | Check the power supply line |

Consulting the advanced new technologies and products of sewage treatment industry:4007800879