Copyright © 2019 Jiefusen(Shanghai) Environmental Protection Technology Co., Ltd. All right reserved.

DesignBy:ShuangXi

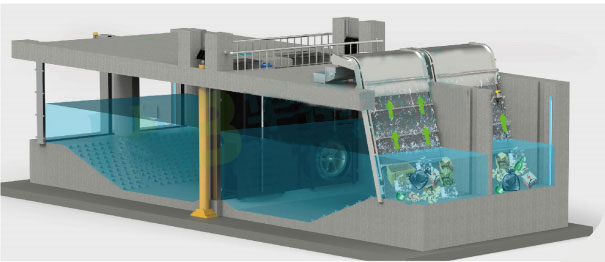

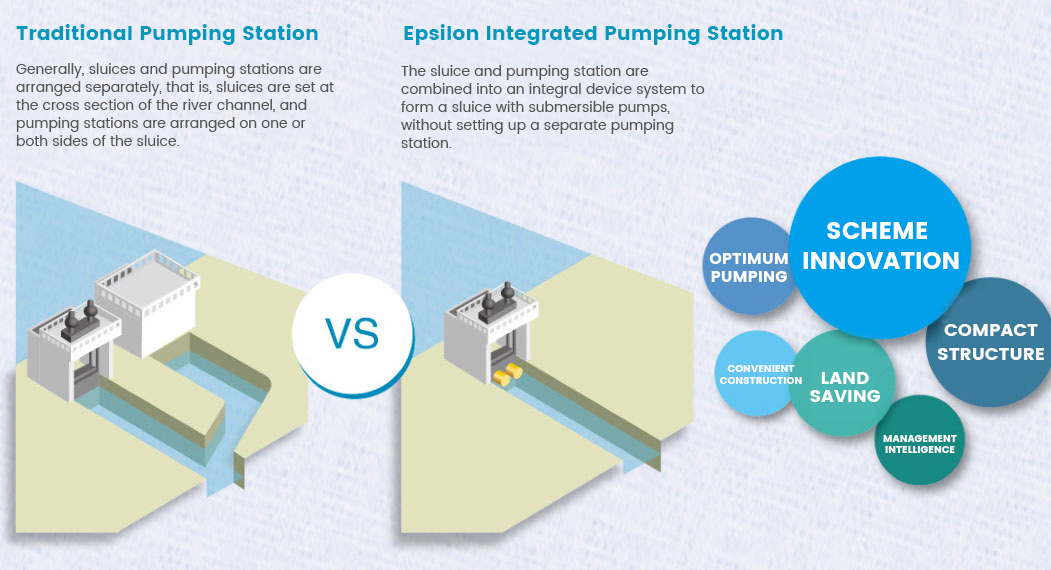

The integrated pump gate can be made of cast iron, stainless steel or GRP fiberglass. It is available in various models. The integrated pump gate includes a sluice gate, submersible pump, gate, sensor configuration and complete control system. Different from the traditional gate station, the design makes full use of the sturdy frame of the sluice, and the sluice is used as the basic structure of the pumping station. The pump and the gate are directly installed on the sluice. The traditional system is more compact and precise without the need for a traditional stand-alone pumping station. The highly integrated monitoring system enables intelligent linkage monitoring of the sluice and pump.

Order Hotline:

+86-4007800879Epsilon can tailor the product type according to your industry, site to be used and other special needs.

Offer consultingA pump gate that integrally arranges a pump station and a brake station. According to the current situation of China's urban drainage system and water conservancy engineering system, our company integrates the practical design and application experience of pump stations and gate stations for many years. It is mainly used for water storage in urban rivers, internal and external rivers. Body and flood control.

In the structure of the integrated pump gate, the gate is both a water retaining structure and a foundation for water pump support. The water pump is arranged on the gate, and a fixed pump chamber is not built, so that the gate and the pumping station are combined into one. The integrated pump gate is an innovative drainage function building consisting of a sluice gate, a gate pump, a gate, a sensor configuration and a complete control system.

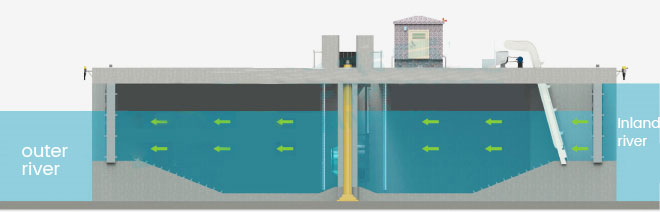

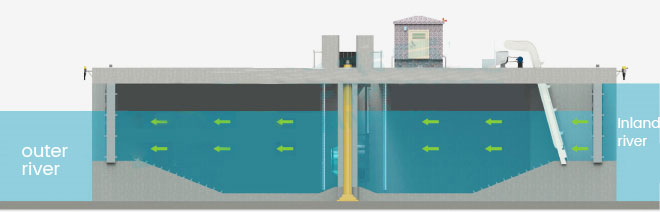

1.Self-flowing drainage: When the water level in the river rises and rises to the high water level warning value, when the water level of the river is lower than the warning value, the gate opens and the water in the river flows to the river to prevent internal sputum; When the water level drops to a safe value, the gate automatically closes.

2.Forced drainage: When the water level in the river rises and rises to the warning value, and the water level of the river is also detected to reach the warning value, the gate is closed, and a single pump is started for strong discharge. When the water level of the river continues to rise, it is simultaneously Turn on two pumps for strong discharge to prevent internal sputum; when the water level drops to a safe value, turn off both pumps at the same time.

1.Self-flow water supply: When the water level in the river is reduced and lowered to the low water level warning value, when the water level of the river is higher than the river water level, the gate is opened and the river is replenished to prevent drought.

2.Mandatory water replenishment: When the inland river water level is lowered and lowered to the low water level warning value, when the outflow water level is not higher than the inland water level, the gate is closed, the system controls the pump group to reverse, so that the pump reverses drainage and forcibly controls the inland river. Replenish water to prevent drought.

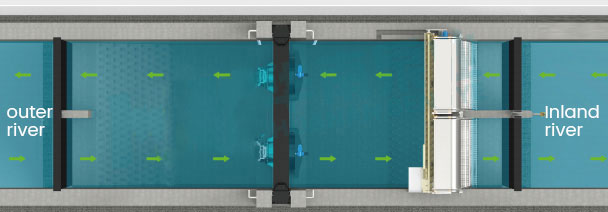

When the river water flow rate is slow, causing the inland river stagnant water phenomenon or increasing the river channel flow rate to send away the river garbage, it is necessary to manually send a signal to control the pump gate to follow the water state; when it is detected that the water level of the river is higher than the water level of the river, the gate is opened. The water in the inland river flows to the outer river; when it is detected that the water level of the river is lower than the water level of the river, the gate is closed and a single pump is started for strong discharge; the above process completes the forward water circulation. When the positive water is completed, the reverse water is used. The principle is the same as the forward water flow, but the pump needs to be the reverse drainage; the above process completes the water exchange.

When it is necessary to salvage the inland river garbage, it is necessary to install a grill machine on the inland side of the pump gate; when it is necessary to clean the sewage, it is possible to control the pump gate to start the grille machine while the water is being forwarded; when it is necessary to salvage the waste water, It is necessary to install a grilling machine on the outer river side of the pump gate; when it is necessary to clean the sewage, it is possible to control the pump gate to perform the reverse water circulation and start the grill machine.

Parameter type | Technical parameters | Remarks |

Product number | 35-1-1——140-1-10 | |

Flow range | 640——144000m³/h | |

Head range | 0.5-12m | |

Distribution power | 7.5-2000kw | |

Voltage specification | 380V、660V、6KV、10KV | |

Medium condition | PH5-9 | Water quality is clean water or mild sewage |

Allowable passage of particle equivalent diameter | ≤1/10Pump outlet diameter | No large amount of fiber impurities |

Working environment | Temperature-20℃——120℃ | Humidity:95% |

Maximum working head | One-way compression:10m One-way compression reverse:5m | Two-way compression, both10m |

Design head | ≤15m | (Including recoil head) |

Orifice width | 0.5m——10m | (Selected according to customer parameters) |

Orifice height | 0.7m——10m | (Selected according to customer parameters) |

Inland design water level | 1m——7m | (Selected according to customer parameters) |

Outer river design water level | 1m——9m | (Selected according to customer parameters) |

Gate orifice size specifications recommended

Width \ mm | Orifice height \ mm | |||||||||

1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 | |

1000 | ● | ● | ||||||||

2000 | ● | ● | ● | |||||||

3000 | ● | ● | ● | |||||||

4000 | ● | ● | ● | ● | ||||||

5000 | ● | ● | ● | ● | ||||||

6000 | ● | ● | ● | ● | ● | ● | ||||

7000 | ● | ● | ● | ● | ||||||

8000 | ● | ● | ● | |||||||

9000 | ● | ● | ● | |||||||

10000 | ● | ● | ||||||||

Consulting the advanced new technologies and products of sewage treatment industry:4007800879